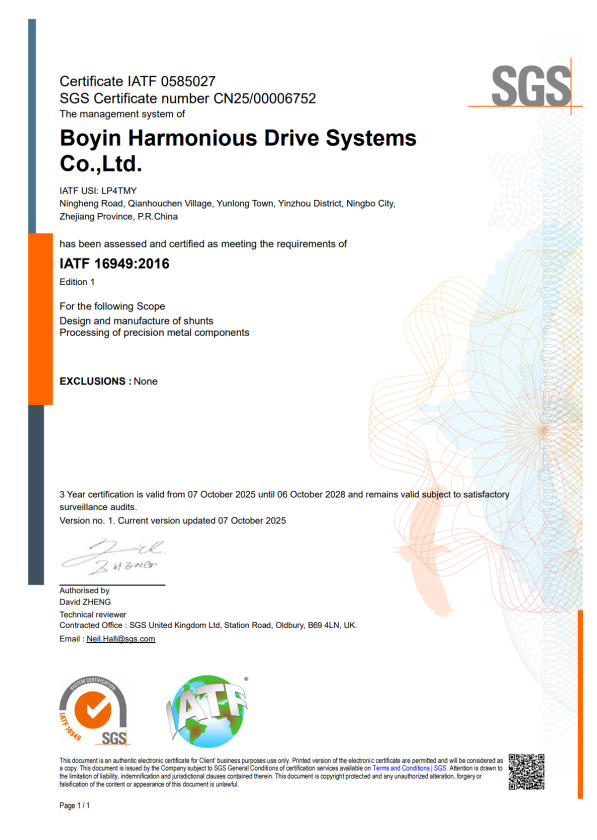

Recently, the shunt business line of Boyin Harmonious Drive Systems Co., Ltd. (hereinafter referred to as "Boyin Drive") has successfully passed the authoritative audit of the International Automotive Task Force (IATF) and officially obtained the IATF16949:2016 Automotive Industry Quality Management System Certification Certificate. This certification not only marks that the R & D, production and quality control systems of its shunt products fully comply with the highest quality standards of the global automotive industry, but also provides an "international pass" for this business to open the door to the core supply chain of new energy vehicles, and at the same time fills the key gap in the quality certification of domestic electron - beam - welded precision shunts in the automotive field.

As the "rigid access threshold" of the automotive industry chain, the IATF16949:2016 standard, on the basis of ISO9001:2015, further strengthens the requirements for defect prevention, process traceability and supply chain collaboration, and mandatorily requires the implementation of five core tools such as APQP (Advanced Product Quality Planning) and MSA (Measurement System Analysis).

Since the preparation for the shunt certification was launched in July 2024, relying on the technical accumulation in the field of precision manufacturing and aiming at the requirements of new energy vehicles for shunts in terms of "high stability, high precision and high reliability", Boyin Drive has constructed a full - chain standardization system of "material R & D - process manufacturing - finished product inspection":At the R & D end, the core process of electron - beam welding is adopted, and a dual - channel multi - resistance integrated structure is developed, which not only realizes the "double - insurance" measurement and control (avoiding the risk of single - channel failure), but also meets the double breakthroughs of miniaturized installation.At the production end, a digital traceability system recognized by German TUV is introduced to conduct real - time monitoring of 12 key indicators such as alloy material proportion and welding parameters, ensuring the traceability of products and the stable and controllable quality.At the inspection end, high - precision equipment certified by the State Grid Metrology Center is configured to ensure that the product sampling accuracy reaches 0.2% and the temperature drift is controlled within ±5ppm/℃, far exceeding the industry average level.

With the strict control of the full chain, the shunt business of Boyin Drive has finally passed the audit with an excellent result of zero non - conformities, laying a solid foundation for the subsequent entry into core scenarios such as the battery management system (BMS) and vehicle - mounted electronic control of new energy vehicles, and also providing a compliance model for the domestic application of precision shunts in the automotive field.